Descripción

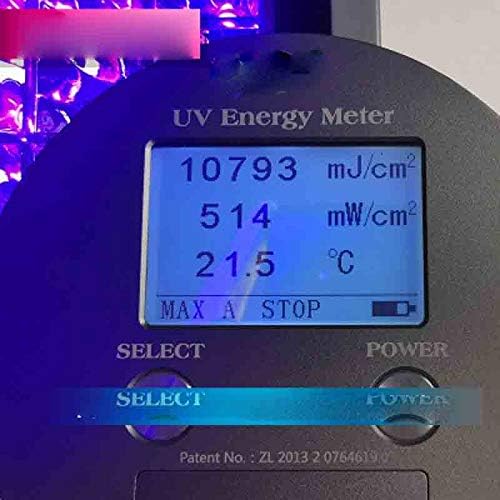

[Features] Cold light source, no heat radiation, low surface temperature rise of the illuminated product, to solve the traditional heat injury problem. Particularly suitable for liquid crystal edge sealing, film printing, etc.;[Usage] LED UV lamp should be as close as possible to the surface of the cured object. The closer the distance, the better, it should be kept within 0.5-1 cm distance. The irradiation distance too far will seriously affect the curing effect;[Scope of use] UV curing (no shadow glue \ ink \ resin film), photochemical catalysis, medical physiotherapy, aging test, UV printing, plastic printing, diazo copier, mobile phone LCD screen and so on.[Tips] To achieve the best and best curing results, you must pay attention to two points:First, the wavelength of the photocuring agent contained in the UV adhesive must be the same as the wavelength emitted by the UV lamp;Second, the UV energy emitted by the UV lamp must meet the energy required to cure the UV glue. The energy of the UV light is proportional to the power of the lamp. (It is best to consult the glue supplier before purchase, the wavelength requirement for UV glue curing).

Características

[Features] Cold light source, no heat radiation, low surface temperature rise of the illuminated product, to solve the traditional heat injury problem. Particularly suitable for liquid crystal edge sealing, film printing, etc.; [Usage] LED UV lamp should be as close as possible to the surface of the cured object. The closer the distance, the better, it should be kept within 0.5-1 cm distance. The irradiation distance too far will seriously affect the curing effect; [Scope of use] UV curing (no shadow glue ink resin film), photochemical catalysis, medical physiotherapy, aging test, UV printing, plastic printing, diazo copier, mobile phone LCD screen and so on. [Tips] To achieve the best and best curing results, you must pay attention to two points: First, the wavelength of the photocuring agent contained in the UV adhesive must be the same as the wavelength emitted by the UV lamp;

Departamento es Unisex-adult

Peso

41.00 Pounds

Fabricante es DLAKHH

Destacados

[Features] Cold light source, no heat radiation, low surface temperature rise of the illuminated product, to solve the traditional heat injury problem. Particularly suitable for liquid crystal edge sealing, film printing, etc.;, [Usage] LED UV lamp should be as close as possible to the surface of the cured object. The closer the distance, the better, it should be kept within 0.5-1 cm distance. The irradiation distance too far will seriously affect the curing effect;, [Scope of use] UV curing (no shadow glue ink resin film), photochemical catalysis, medical physiotherapy, aging test, UV printing, plastic printing, diazo copier, mobile phone LCD screen and so on., [Tips] To achieve the best and best curing results, you must pay attention to two points:, First, the wavelength of the photocuring agent contained in the UV adhesive must be the same as the wavelength emitted by the UV lamp;

El País de Origen (COO, siglas en inglés) o fabricación del producto UV Curing lamp LED UV shadowless lamp 365nm 395nm 405nm Printing Exposure banknote Mobile Phone Screen Glass bonding Green Oil (Color 365nm, Size 250W) es China.

$3,235,777

Lámparas LEDUV Curing lamp LED UV shadowless lamp 365nm 395nm 405nm Printing Exposure banknote Mobile Phone Screen Glass bonding Green Oil (Color 365nm, Size

Disponibilidad: 7 disponibles

Ventajas de Comprar en Yaxa

- Envío gratuito para compras superiores a $179.900 en 1 o más productos

- Pagos seguros - La pasarela es la que procesa y almacena tu pago

- Compras Empresariales - Se entrega Factura Electrónica

- Compra Internacional

- Tiempo de entrega de 7 a 15 días hábiles

[Features] Cold light source, no heat radiation, low surface temperature rise of the illuminated product, to solve the traditional heat injury problem. Particularly suitable for liquid crystal edge sealing, film printing, etc.;, [Usage] LED UV lamp should be as close as possible to the surface of the cured object. The closer the distance, the better, it should be kept within 0.5-1 cm distance. The irradiation distance too far will seriously affect the curing effect;, [Scope of use] UV curing (no shadow glue ink resin film), photochemical catalysis, medical physiotherapy, aging test, UV printing, plastic printing, diazo copier, mobile phone LCD screen and so on., [Tips] To achieve the best and best curing results, you must pay attention to two points:, First, the wavelength of the photocuring agent contained in the UV adhesive must be the same as the wavelength emitted by the UV lamp;

Descripción

Información adicional

| Peso | 41.00 kg |

|---|

Valoraciones

No hay valoraciones aún.